Company offers series of PCB labels with unique material compositions that protect against harsh chemical washes & high temperatures.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – will present the challenges associated with cleaning- and heat-related PCB label adhesion and legibility issues during the SMTA High Reliability Cleaning & Conformal Coating Conference (CCCC), which takes place in Dallas from August 29-31. Shahela Ali, Director of Global Marketing for IDENTCO, will present PCB Labels & Cleaning Agents: Critical Compatibility on August 30 at 3pm.

Despite frequently being overlooked, the ways in which labels and labeling components interact in cleaning and coating environments is crucial. In electronics manufacturing, the relationship between these two distinct disciplines is both symbiotic and fundamental. Printed circuit boards must be clean – and must also be clearly marked and reliably traceable.

Ms. Ali’s presentation will explore this mission-critical topic, including an overview of labeling materials best suited to withstand powerful cleaning agents and harsh SMT environments. It also will discuss the need for conformal coaters and cleaning agent providers to work more synergistically with labeling experts to collectively serve electronics customers.

IDENTCO was selected to present largely due to its prowess in this niche. At Booth #4, the company will showcase one of its latest series of labels for PCB applications, featuring a substrate developed exclusively for IDENTCO by a prominent industry materials and coating supplier. Called TT413, the labels easily withstand prolonged, repeated exposure to the chemicals and high temperatures typical to post-production washing processes. Helpfully, the series is designed for on-demand thermal transfer printing of variable information – a plus for electronics companies incorporating serialization and/or anti-counterfeiting coding into their production practices.

During her presentation, Ms. Ali will elaborate on the broad range of factors that commonly impact PCB labeling durability.

“PCB labels can experience any number of critical failures due to cleaning agents or high temperatures, from fading and flaking to smearing and even complete detachment or disappearance,” said Ms. Ali. “I look forward to discussing solutions to these pitfalls, including the importance of real-world scenario testing and equipping PCB labels with materials-science based endurance and protection.”

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

IDENTCO Designs Custom Labeling Solution for Industrial OEM with Enhanced Cleaning Agent Resistance and Exponentially Reduced Price Point

Developed specifically for prominent fluid management systems OEM, IDENTCO’s TT656 labels also simplify production process while offering broader range of ribbon lengths and widths.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has introduced a new labeling system for the industrial sector that simplifies the manufacturing process while providing unprecedented levels of resistance against harsh cleaning agents. Designed specifically for a prominent fluid management systems OEM, the company’s TT656 Label Series solves for many common sector-specific marking and identification stumbling blocks even while offering the potential for streamlined production and exponential cost savings.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has introduced a new labeling system for the industrial sector that simplifies the manufacturing process while providing unprecedented levels of resistance against harsh cleaning agents. Designed specifically for a prominent fluid management systems OEM, the company’s TT656 Label Series solves for many common sector-specific marking and identification stumbling blocks even while offering the potential for streamlined production and exponential cost savings.

Before engaging IDENTCO for a custom solution, the fluid management systems company utilized several labeling methods – each with their own drawbacks. Like practically all industrial equipment, the apparatus’ labels needed to endure aggressive cleaning agents while remaining flawlessly legible. The OEM initially employed a system where a clear label was manually placed atop the printed-upon base label. In addition to requiring an onerous amount of labor, the setup was subject to human error such as overlooking the clear, protective top layer.

The fluid management system OEM eventually transitioned to a multilayer windowed label. While an improvement, issues with available printing real estate and printer compatibility issues left the supplier seeking further improvements.

IDENTCO’s TT656 Series amounted to a custom-designed sweet spot. The single-layer labels do not require an overlaminate, nor do they incorporate a relatively complex windowed structure. Crucially, TT656 labels withstand a more comprehensive range of cleaning agents compared with other single-layer industrial labeling solutions, and are available in an expanded array of ribbon lengths and widths. The new labeling system also displayed superior adhesion to both stainless steel and polypropylene and, while competing solutions were experiencing lead times of more than two months, IDENTCO is supplying TT656 labels within two weeks of order receipt.

Despite its many advantages, though, perhaps the most notable benefit IDENTCO’s fluid management system customer is enjoying is the price point. The switch to TT656 labels is providing the OEM with a percentage savings in the high triple digits, meaning it is several times less expensive than its previous solution.

Offering excellent smudge, abrasion, scratch and solvent resistance, IDENTCO’s TT656 Series of labels is suitable for indoor and limited outdoor applications. It consists of a 2.6 mil gloss white face stock with a 1.0-1.1 mil acrylic adhesive and a 50# kraft liner. When used in combination with IDENTCO’s TTRR-T ribbon, it passes a large variety of chemical durability performance tests.

“Industrial equipment is understandably subjected to aggressive cleaning agents, which can render vital product markings eroded, illegible or even unaffixed,” said Ralph Rhein, Technical Director for IDENTCO. “Our new TT656 labels may be our most chemical-resistant industrial marking solutions to date, and bring the added benefits of optimized labor, expanded options for label size, tight-turnaround lead times and drastically reduced cost.”

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

IDENTCO Introduces Automated Wire Marking System

Ideal for applying self-laminating & flag labels to wires, cables & harnesses, company’s durable VortexID® can handle up to 20 products per minute and operate 24/7.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has introduced an automated wire marking system whose stamina and speed set new benchmarks for wire and harness label application. The company’s VortexID® can precisely apply up to 20 labels per minute – outpacing other automated units and doubling the most expedient manual setups – and operate 24/7, a stark departure from the single-shift limitations of competing models.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has introduced an automated wire marking system whose stamina and speed set new benchmarks for wire and harness label application. The company’s VortexID® can precisely apply up to 20 labels per minute – outpacing other automated units and doubling the most expedient manual setups – and operate 24/7, a stark departure from the single-shift limitations of competing models.

Capable of handling a variety of American wire gauge sizes (AWGs), IDENTCO’s VortexID® automated wire marking system is suitable for a broad range of sectors whose products incorporate wires and harnesses, most notably electronics and automotive components production. The module features 300dpi printing capabilities, with labels applied via a vacuum plate with a rotating mechanism for reliable application on cylindrical products. Notably, IDENTCO’s new module is materials agnostic, expanding customer choice and potentially decreasing overall labeling materials costs.

The VortexID® can apply both self-laminating and flag labels, an attractive two-for-one modularity accomplished by an interchangeable applicator. This inherent versatility serves as another differentiator in its space, providing customers with a flexible solution eliminating the need to purchase specific machines for each label type. For both label types, the VortexID’s application consistency and repeatability ensure neat, secure labels where crucial product, traceability and electronics testing information is pristinely printed and unobscured.

The module’s robustness is arguably its most groundbreaking strength. Whereas modules from leading competitors generally max out at eight hours of continuous operation, the VortexID® can operate continuously, bringing the potential for thousands more processed products over the course of just a single day.

“As the demand for high-volume wire and harness manufacturing grows ever stronger, solutions that can automate key aspects along the production line – including, of course, the labeling process – are increasingly sought-after,” said Emilio Garza, Automation Manager for IDENTCO. “Our new VortexID® automated wire marking unit combines high throughput and continuous operation with the precision printing and label placement necessary to ensure long-term information readability.”

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

IDENTCO® Names Brad Zechman as New CEO

Executive brings three decades of automotive, electronics & industrial expertise and leadership to prominent labeling solutions provider.

Executive brings three decades of automotive, electronics & industrial expertise and leadership to prominent labeling solutions provider.

Ingleside, IL – IDENTCO® – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has appointed longtime materials supply executive Brad Zechman as its newest CEO. He officially joined the company on April 10, and will be responsible for overseeing all strategic business, sales and product development direction across each of IDENTCO’s four major business units. Mr. Zechman also is CEO of Reliance Label Solutions.

Most recently, Mr. Zechman served as president of Pennsylvania-based Adhesives Research, where his implementation of a commercial transformation linked to a more suitable operational strategy lead to significant growth. Prior to that, he spent three years as VP of Global Packaging for Minnesota-based HB Fuller, where he oversaw strategies that helped mitigate the then-deflationary raw materials market. Before that, he spent a decade with specialty materials and electromechanical solutions company LORD, where his leadership led to exponential growth.

Mr. Zechman joins IDENTCO at a promising time. The company has been steadily adding to its extensive portfolio of labeling solutions, which it designs, manufactures and supplies for demanding sectors such as automotive components, electronics applications, industrial machinery & tools, and commercial transportation. Among other products, IDENTCO specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance and identification.

Mr. Zechman is replacing IDENTCO CEO and founder Scott Lucas, who is retiring after an impressive 37 years with the company. Through the decades, Mr. Lucas’ stewardship helped take IDENTCO from a promising labeling and marking solutions startup to the robust, globally-focused organization it is today. Mr. Lucas has assumed the title of Chief Strategic Relations Officer.

“I am honored to step into the role of a true industry pioneer like Scott, and look forward to helping build upon what he helped create as IDENTCO enters a new chapter,” said Mr. Zechman. “We’ll continue to expand our solutions portfolio across each of our four main business units, with the goal of further increasing our market presence in each.”

Mr. Zechman earned a degree in chemical engineering from Rutgers University in New Jersey, and an MBA in finance from Wharton School of Business, University of Pennsylvania.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible. For more information, visit www.identco.com.

IDENTCO® Introduces PCB Labels with Unique Material Composition That Protects Against Chemical Washes & High Temperatures

IDENTCO® Introduces PCB Labels with

Unique Material Composition That Protects Against Chemical Washes & High Temperatures

New TT413 labeling seri es offers vital identification and traceability

es offers vital identification and traceability

for high-leverage printed circuit board components.

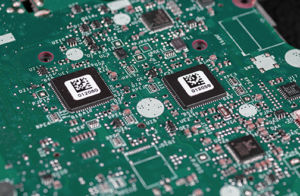

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has introduced a robust series of labels for printed circuit board (PCB) applications that features a substrate developed exclusively for IDENTCO by a prominent industry materials and coating supplier. Providing vital identification and traceability for high-leverage PCB components, the new TT413 labeling series easily withstands prolonged, repeated exposure to the chemicals and high temperatures typical to post-production washing processes.

IDENTCO’s TT413 portfolio is designed for on-demand thermal transfer printing of variable information – a plus for electronics companies incorporating serialization and/or anti-counterfeiting coding into their production practices. A 2.4 mil gloss white polyimide provides exemplary, ultra-durable resistance against smudges, solvent, heat, and abrasion, and serves as a receptive surface for a variety of thermal transfer ribbons from IDENTCO.

TT413 labels feature a 2.0 mil ultra-aggressive permanent acrylic adhesive that, like the product’s printable materials, offers excellent resistance to harsh chemicals and high temperatures. Its adhesive power is equally impressive, with tests showing a 20-minute dwell with a peel adhesion strength of 40oz/in or higher for both stainless steel and PC board. At 24 hours, the labels boast dwell strengths of 43oz/in for epoxy, and an especially strong 55oz/in for stainless steel.

The new labeling solutions are ideally suited to a wide array of electronics components manufacturing environments, including box builds, internal and external vehicle parts (such as in-cabin infotainment systems and outside sensors), and various other computer unit and PCB assembly settings.

“Featuring a substrate developed specifically for IDENTCO, the new TT413 series is designed to meet the type of demanding durable labeling requirements inherent to various PCB applications and electronics components production,” said Victor Holbein, Chief Operating Officer for IDENTCO. “Its special polyimide allows it to provide exceptional levels of durability and functionality at an exceedingly cost-effective price point.”

IDENTCO’s TT413 labels are available in release liners composed of 55# glassine or 1.5 mil polyester, each suitable for both automated or manual application processes.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible. For more information, visit www.identco.com.

IDENTCO® Displays New Labeling Solutions & Automation Capabilities at Three Electronics Trade Shows

IDENTCO® Displays New Labeling Solutions & Automation Capabilities at Three Electronics Trade Shows

Company also showcases results of thorough polyimide

testing against harsh PCB cleaning chemicals.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – highlighted new labeling solutions, proven polyimide ruggedness and enhancements to its automation capabilities at three electronics sectors in May: PCB East, May 9-11 in Boxborough, MA; SMTA Wisconsin, May 16 in Milwaukee; and SMTA Mexico, May 18 in Juarez.

For starters, IDENTCO exhibited its brand new series of robust labels for printed circuit board (PCB) applications, featuring a substrate developed exclusively for IDENTCO by a prominent, global industry materials and coating supplier. Providing vital identification and traceability for high-leverage PCB components, the new TT413 labeling series easily withstands prolonged, repeated exposure to the chemicals and high temperatures typical to post-production washing processes. The portfolio is designed for on-demand thermal transfer printing of variable information – a plus for electronics companies incorporating serialization and/or anti-counterfeiting coding into their production practices.

In fact, a broad array of IDENTCO’s labeling solutions are proven to stand up against repeated exposure to the aggressive cleaning chemicals common in PCB manufacturing. At each show, IDENTCO touted its close collaboration with leading cleaning solutions providers. Each company recently completed the latest in an ongoing series of tests ensuring the durability and legibility of polyimides utilized in various IDENTCO products.

IDENTCO also highlighted its portfolio of wire harness label products for a wide range of applications, including electronics and automative components manufacturing. Among other marking solutions, the company’s TTL200 self-laminating labels offer the most opaque white print-on area on the market, and are available for an extensive array of wire and harness shapes and sizes. The TTL200 series also provides the flexibility of printer agnosticism, as the labels are compatible with all major printer types and brands.

Automation was another key theme for IDENTCO. The company strives to help simplify the automation process for PCB manufacturers through labeling solutions offering plug-and-play functionality with most SMT equipment brands. At the shows, IDENTCO stressed the importance of seamlessness in automation, and highlighted its comprehensives labels + equipment packages designed for hassle-free integration. Moving forward, IDENTCO is primed to introduce a new automated solution in the wire marking category in the coming weeks.

“Everything we do is designed to make labeling solutions the last thing PCB manufacturers need to worry about,” said Brad Zechman, who became IDENTCO’s CEO in April. “From marking solutions that withstand high temperatures and repeated exposure to harsh cleaning agents, to simplified labeling to key components like wires and harnesses, to brand-agnostic automation and line integration – IDENTCO provides our customers with user-friendly solutions for complex production environments.”

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible. For more information, visit www.identco.com.