We offer a comprehensive portfolio of pressure-sensitive label solutions that address the broad range of demanding automotive applications including under-hood, brake systems, interior, steering & suspension, and electrical & electronic systems.

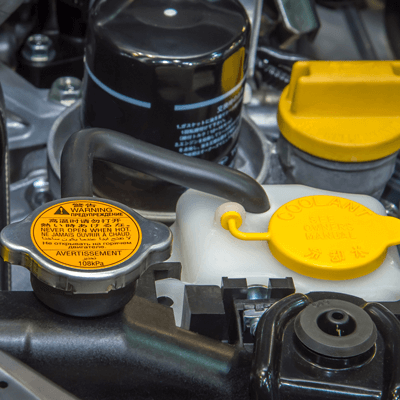

Under-Hood

Under-hood applications require labeling solutions that must reliably display critical information through extended use and under harsh conditions, as well as satisfy a range of OEM specifications and compliance regulations.

- Broad automotive-ready portfolio of labels ensures best fit-for-purpose product selection

- White and chrome PET with high performance adhesives pre-qualified with major Car Makers

- Extensive performance test data documented and available to OEM

- On-demand thermal transfer printing solutions provide excellent resistance to heat, oils, solvents and other harsh chemicals

Applications

Interior

Our in-vehicle labels reliably identify air bags, seat belts, sensors and other systems designed to keep passengers safe.

- Air bag sensor & warning labels

- Capacity & ratings labels, including vehicle load capacity labels

- Serialized barcode labels for product recalls

Applications

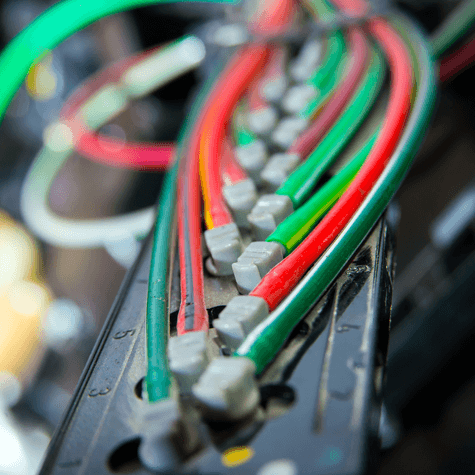

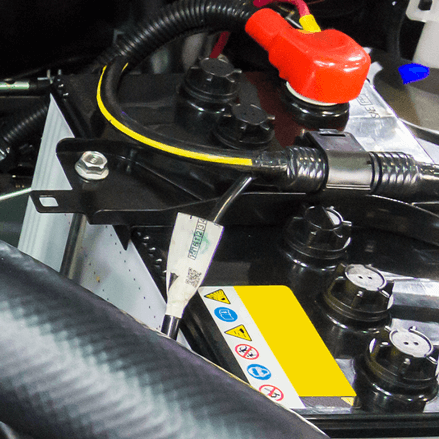

Electrical Systems

As a recognized leader in automotive labeling applications, we continuously develop innovative, cost effective solutions that meet exacting automotive OEM requirements. From identifying under-hood wiring harnesses to labeling Advance Driver Assistance Systems (ADAS), we offer a comprehensive range of electrical and electronics identification solutions.

- Automotive-ready portfolio ensures OEM and Tier 1 compliance

- Broad range of durable material sciences offers fit-for-purpose, cost effective solutions

- In-house reliability & performance testing lab results in faster performance validation

- Pre-printed combination labels offer the flexibility of printing on-demand variable data

Applications

Steering & Suspension

Our steering and suspension labeling solutions are engineered to perform in harsh environments and tailored for low energy substrates often found in those applications.

- Engineered for high performance on most low energy surfaces

- Specially engineered topcoats resist chemical exposure along with abrasion and salt spray

- Available in blank or pre-printed combinations for on-demand variable data printing

- In-house reliability and performance testing lab enhances NPI prototyping

Applications

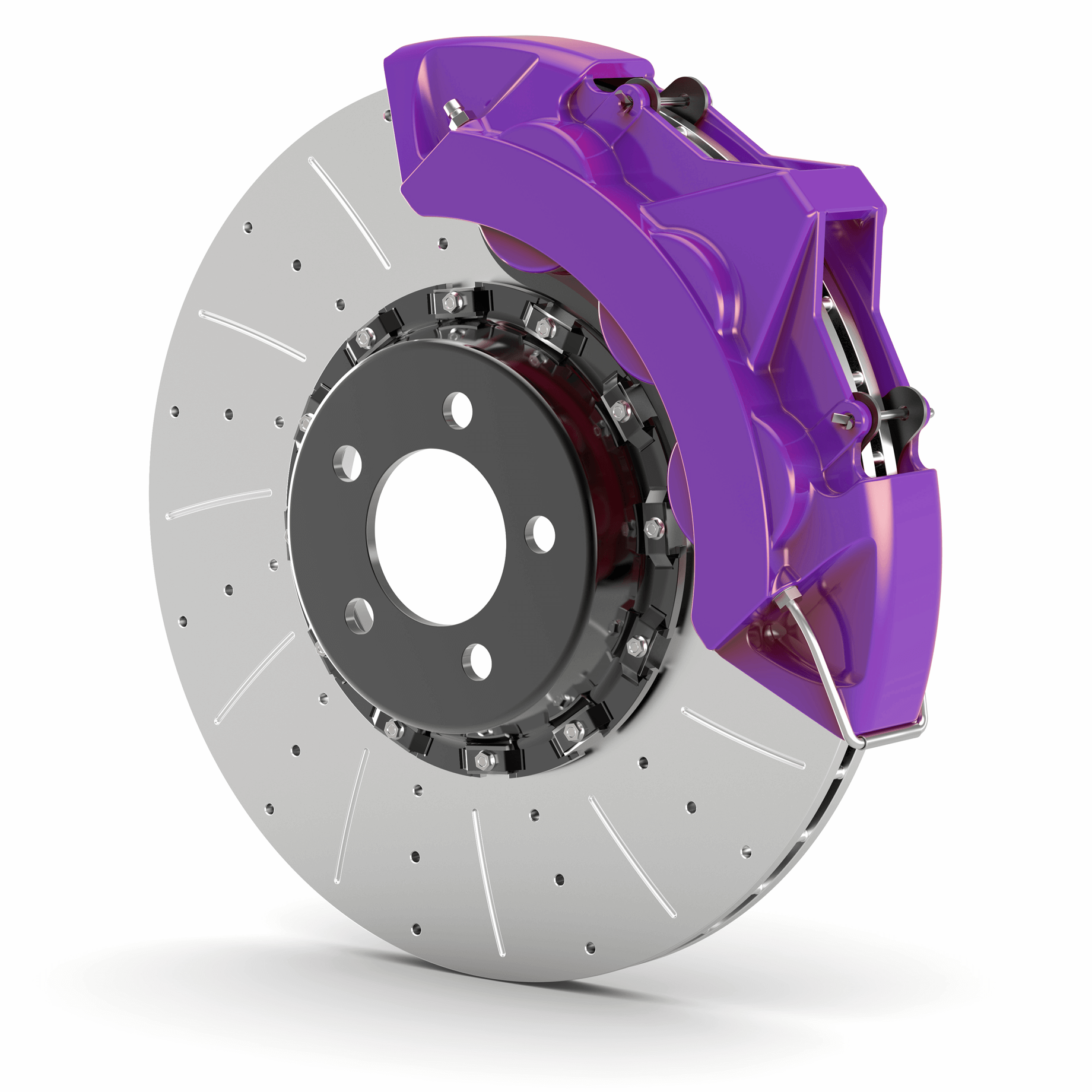

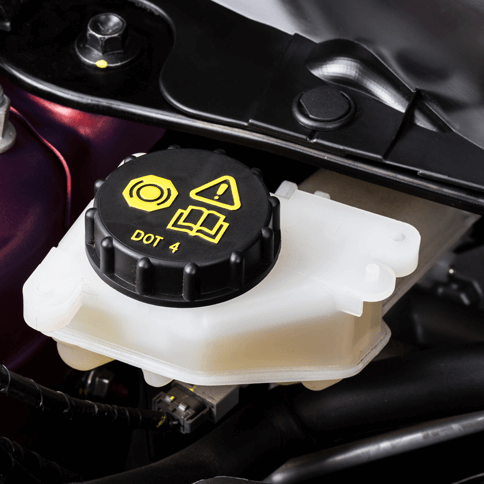

Braking Systems

Our labeling solutions for braking systems, including heat shrink identification for brake lines and ABS control module labels, are designed to withstand harsh under-the-car environments and perform reliably for a lifetime of use.

- Aftermarket heat shrink branding on brake lines

- ABS control module labels & PCB labels inside control modules

- Designed to withstand exposure to brake fluid

- Brake line heat shrink ID to show DOT certification

- Identification labels on braking components such as ABS pump control module

Warning & Caution

Warning & Caution  Rating & Nameplate

Rating & Nameplate  Instructional, Control & Connection

Instructional, Control & Connection  Warning & Caution

Warning & Caution  Instructional

Instructional  Track & Trace

Track & Trace  Rating & Nameplate

Rating & Nameplate  Wire & Cable Identification

Wire & Cable Identification  Track & Trace

Track & Trace  Instructional, Control & Connection

Instructional, Control & Connection  Rating & Nameplate

Rating & Nameplate  Track & Trace

Track & Trace  Instructional, Control & Connection

Instructional, Control & Connection  Branding

Branding