FOR IMMEDIATE RELEASE

FOR IMMEDIATE RELEASE

INGLESIDE, Ill. (September 29, 2017) – At the upcoming productronica show in Munich, Germany, IDENTCO will showcase an extensive portfolio of solutions for on-demand identification needs.

IDENTCO’s booth in Messe Munchen Hall A will feature:

- Thermal Transfer and Die-Cut Parts Materials Portfolio

- “Economy vs High-Performance” Strategy to Manage PCBA Labeling Costs

- Material and Converting R&D Advancements

- Auto-Apply Solutions

“Productronica is not only a crucial exhibition for the European market, but proves to be an essential place to network on a global scale. It is at this event where key players showcase their latest innovations that will shape the future of the electronics industry,” said Katherine Blake, IDENTCO’s new Director of Sales for Europe.

Thermal Transfer and Die-Cut Parts Materials Portfolio

IDENTCO’s broad catalog of thermal transfer PCBA solutions features stock blank labels, custom blank and pre-printed labels, as well as options for presenting via auto-apply equipment. IDENTCO’s array of ribbons, printers, scanners, re-winders, dispensers and SMT label feeders will also be on display.

One of the newest product offerings is the PPL line of polyimide labels for auto-application on the SMT production line. Precision die-cut labels on quick release liners in the IDENTCO-engineered REEL-e™ format ensures static-free delivery of labels.

“Economy vs High-Performance” Strategy to Manage PCBA Labeling Costs

Polyimide labels are designed for high-temperature, harsh-environment applications, but not all polyimides are the same and not all applications require the same level of durability and performance.

IDENTCO’s product development team and application engineers evaluate customers’ specific applications to determine which products will deliver the best “fit for purpose” label material construction to deliver the lowest cost of ownership.

“A lot of electronics customers don’t realize that their labels are probably over-engineered,” Director of Thermal Transfer Products Craig Fransen explained. “With IDENTCO’s ‘good-better-best strategy’, we offer a range of label materials to achieve the balance between cost and performance for each specific label application, and can typically save our customers 15 percent on polyimide labeling applications.”

Material and Converting R&D Advancements

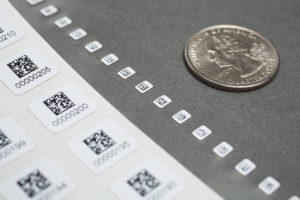

EMS customers are continually pushing for smaller and smaller labels to improve the traceability of their products. IDENTCO continues to engineer smaller formats enabling printing and presenting for even the tightest applications. As label experts, customers rely on IDENTCO to understand and deliver on their PCBA labeling requirements and IDENTCO continues to innovate with labels as small as 2mmx2mm.

Auto-Apply Solutions

Labels not only need to be printed, but also applied. Manually applying labels at high rates is challenging and often results in inconsistent placement and poor adhesion performance. IDENTCO’s ELP-A auto-apply applicator portfolio offers cost-effective solutions to ensure consistent label presentation at high rates. The applicators, which will be on display at IDENTCO’s booth, are designed to handle a broad range of sizes and shapes on a wide array of automation systems.

About IDENTCO

Headquartered outside Chicago, IDENTCO has been delivering technology-driven, high-performance labeling solutions since 1986. We challenge ourselves to develop innovative solutions that can withstand any number of extremes and meet the strictest performance standards. With ISO-certified manufacturing facilities in the U.S., Mexico and Germany, we have a global presence and local expertise. For more information, visit www.identco.com.

Contact: Jill Morino, jmorino@identco.com, 815-385-0011 Ext. 207