Company’s durable, precision-minded solutions address specific labeling and traceability requirements for printed circuit boards and various electronic components.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – will showcase its robust range of solutions for printed circuit boards (PCBs) and electronic components at IPC APEX Expo, March 18-20 in Anaheim. Products shown at the company’s Booth 2632 include a selection of sector-specific presenters and labels that meet the industry’s elevated requirements for durability, reliability and overall quality.

For starters, IDENTCO will highlight its range of high-performance label presenters. Designed for seamless integration into surface mount technology (SMT) pick-and-place machines, the presenters allow exacting, automatic placement of the company's PPL™ pick-and-place labels. Hassle-free setup, fast label loading and quick changeover minimize downtime, and the presenters’ precision and reliability help keep production lines running at optimized performance. Compact and durable, the presenters also mitigate cost and labor by minimizing necessary maintenance.

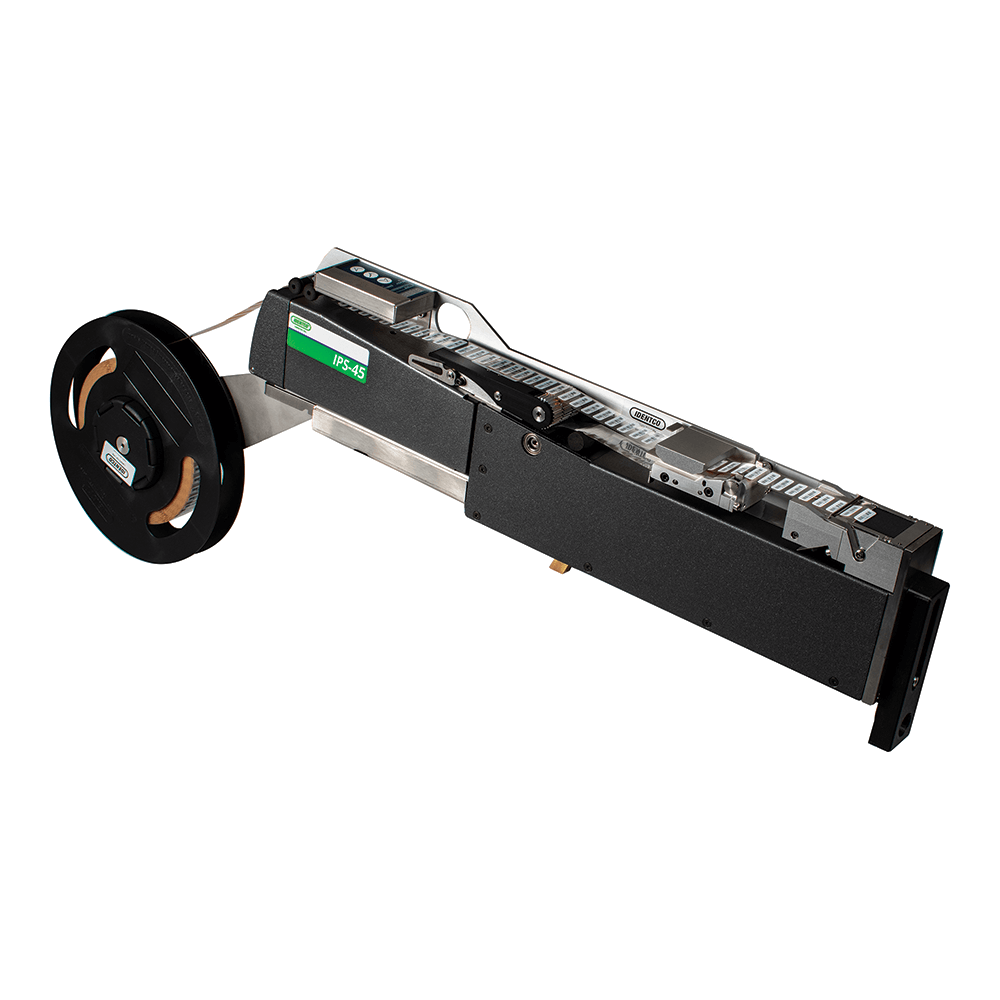

To further showcase the benefits of these products, IDENTCO will provide live demonstrations of its IPS-45 Label Presenter, engineered for SMT applications requiring a broader range of label sizes. The IPS-45 can handle labels from 4x4mm to 27x25mm, combining reliability with much-needed flexibility in an ever-evolving production landscape.

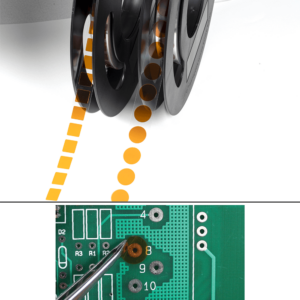

Also at IPC APEX, IDENTCO will showcase the aforementioned PPL™ pick-and-place label series, which provides comprehensive traceability for printed circuit boards and electronic components. Providing seamless integration into SMT as well as the overall assembly process, PPL™ thermal transfer printable labels withstand harsh fluxes, advanced cleaning chemistries and extreme temperatures that circuit boards typically encounter on each side. The labels’ durability ensures full compatibility with track & trace systems – an increasingly valuable feature for brand owners seeking enhanced internal quality control and supply chain transparency in high-value electronics production.

IDENTCO Launches Online Store for Seamless Purchase & Resupply of Thermal Transfer Solutions

shop.IDENTCO.com offers streamlined ordering for company’s durable, functional labels for printed circuit boards, electronic components, and wires and cables, as well as complementary ribbons and printers

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has launched an online storefront offering a one-stop shop for an array of labeling solutions.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has launched an online storefront offering a one-stop shop for an array of labeling solutions.

shop.identco.com allows visitors to peruse and purchase the company’s durable, functional labels across a variety of categories, including those for printed circuit board (PCB) and electronic components, as well as solutions for reliable wire and cable marking. IDENTCO’s broad range of complementary ribbons and printers also are available through the online store.

“Our new online store is designed with customers in mind to provide the most convenient way to purchase and resupply IDENTCO’s wide range of mission-critical labels, ribbons and ancillary solutions,” said Shahela Ali, Director of Global Marketing for IDENTCO. “The ability to place orders with just a few clicks helps expedite purchase order generation and overall delivery and exemplifies our commitment to customer satisfaction.”

Among the marquee products available through the new site is IDENTCO’s DuraTrack series, a set of robust label solutions for printed circuit board (PCB) applications. The DuraTrack series provides PCB assemblies with comprehensive traceability – an increasingly attractive internal quality control and supply chain transparency feature for brand owners producing high-leverage electronics. Engineered for use in surface mount technology and throughout the entire assembly process, DuraTrack thermal transfer printable labels can endure harsh fluxes, the latest cleaning chemistries, and high temperatures encountered in today’s circuit board assembly processes.

The online storefront also will feature a selection of IDENTCO’s labeling and marking solutions for wires and cables, including DuraWrap and DuraFlag. Suitable for a variety of wires and cables, DuraWrap labels are self-laminating cable and harness products combining the functionality of traditional wire label wrapping with the convenience of fully automated self-laminating technology. The exceptionally durable clear wrap-around area reliably withstands chemicals and scratches, ensuring markers remain both affixed and legible.

Meanwhile, self-laminating DuraFlag labels allow for easy and explicit flagging of wires and wire harnesses. This provides a simple way to identify and organize wires, even in harsh conditions such as high temperatures, moisture, and chemical exposure.

IDENTCO’s High-Performance DuraChem Labels Suitable for a Variety of Industries

Previously known as the TTL®700 Series, DuraChem labels offer chemical, solvent, abrasion, and smudge resistance for both indoor and outdoor use. Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sectors – has renamed its stock TTL®700 Series. Now called DuraChem, this highly durable series of labels is constructed from white gloss polyester, a versatile material that can adhere to a wide variety of standard smooth surfaces.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sectors – has renamed its stock TTL®700 Series. Now called DuraChem, this highly durable series of labels is constructed from white gloss polyester, a versatile material that can adhere to a wide variety of standard smooth surfaces.

Featuring a solvent adhesive and gloss topcoat that offers excellent chemical, solvent, abrasion, and smudge resistance, DuraChem has 2-year UL, CUL and CSA ratings for both indoor and outdoor use. Additionally, this series can withstand temperatures of up to 150 degrees Celsius. These attributes make DuraChem labels an ideal choice for a variety of industries including medical, industrial, electronics, military, and automotive.

The DuraChem series offers an assortment of face stock, adhesive and liner combinations that allow for things like UV flexographic, digital pre-printing, and on-demand thermal transfer printing of variable information.

In terms of application, this labels series offers flexibility in that it can be both hand-applied or auto-applied, depending on the circumstance. DuraChem labels can be supplied blank or pre-printed with the option of variable printing conveniently done at a customer’s location.

When used in combination with the recommended IDENTCO ribbon, DuraChem labels meet the most demanding durable labeling requirements.

IDENTCO Offers DuraWrap and DuraFlag Label Products for Wire and Cable Marking

TTL®200 Series renamed to better reflect the advantages of these print-on-demand, self-laminating wire and cable markers for heavy-duty applications

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sectors – has renamed its stock TTL®200 Series. Now called DuraWrap and DuraFlag, the high-performance set of print-on-demand labels provides a convenient way to mark wires, cables, and wire harnesses.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sectors – has renamed its stock TTL®200 Series. Now called DuraWrap and DuraFlag, the high-performance set of print-on-demand labels provides a convenient way to mark wires, cables, and wire harnesses.

Suitable for a variety of wires and cables, DuraWrap labels are self-laminating cable and harness products combining the functionality of traditional wire label wrapping with the convenience of fully automated self-laminating technology. The exceptionally durable clear wrap-around area reliably withstands chemicals and scratches, ensuring markers remain both affixed and legible.

Meanwhile, self-laminating DuraFlag labels allow for easy and explicit flagging of wires and wire harnesses. This provides a simple way to identify and organize wires, even in harsh conditions such as high temperatures, moisture, and chemical exposure.

The recently redesigned series offers the opaquest white print-on area in the industry, ensuring the legend remains clearly legible when marking, even on the deepest black insulation.

A nod to production simplicity, three site holes make the series compatible with any common thermal transfer printer, regardless of sensor location. A perforated liner between each row of labels allows for easy kitting and distribution to individual harness boards or panels. Horizontal, one-across configurations offer even more flexibility for kitting and waste reduction.

Comprised of supple, conformable vinyl material and high-performance acrylic adhesive, the series is available in over 40 sizes and can be used post-termination.

DuraWrap and DuraFlag labels can cover AWG sizes 10 through 4/0 and IEC 60228 (mm2) sizes 6 through 625, from four to 40 conductors wide.

IDENTCO Highlights Automation Capabilities and PCB Labeling at PCB East

Company to showcase label feeders and product solutions to simplify automation.

Company to showcase label feeders and product solutions to simplify automation.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – will highlight its automation capabilities and PCB labeling solutions at PCB East, June 4-7 in Boxborough, MA, Booth #301.

With automation a key theme, IDENTCO’s commitment to simplifying the automation process for PCB manufacturers is evident through the company’s comprehensive label and equipment packages. Designed for hassle-free integration, IDENTCO’s automation products offer plug-and-play functionality with most SMT equipment brands.

Attendees of the show will have the opportunity for a live demonstration of the IPS-30 Slimline Label Feeder. At a mere 30mm (1.18 in.) wide – half the size of conventional feeders – the IPS-30 requires only one feeder position on pick and place machines, freeing up valuable space along congested SMT production lines. Providing precise and accurate placement, it can also feed labels or die cut parts as small as 2mm x 2mm.

Additionally, IDENTCO offers the IPS-45, a presenter ideal for applications requiring a wider variety in label size.

The company will also be exhibiting their robust label solutions for printed circuit board (PCB) applications, including DuraTrack. This label series provides printed circuit assemblies with comprehensive traceability – an increasingly attractive internal quality control and supply chain transparency feature for brand owners producing high-leverage electronics.

Engineered for use in surface mount technology and throughout the entire assembly process, DuraTrack thermal transfer printable labels can endure harsh fluxes, the latest cleaning chemistries, and high temperatures encountered in today’s circuit board assembly processes, on both sides of the board.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

At IPC APEX Expo, IDENTCO to Demo Space-saving Pick & Place Label Presenter, Among Other Solutions

IDENTCO also will demonstrate its robust VortexID® automated wire marking system, and PCB label series with company-exclusive substrate.

Ingleside, IL – IDENTCO, a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector, will highlight a variety of electronics marking systems and products at IPC APEX Expo, April 6-11 in Anaheim, CA. Among other solutions, at its Booth #3823 the company will offer live demonstrations of ILP-30 Slimline Label Feeder for pre-printed label placement. Named for its slender 30mm width – half that of conventional feeders – the label presenter requires only one feeder position on pick & place machines, freeing up valuable space along congested SMT production lines.

Ingleside, IL – IDENTCO, a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector, will highlight a variety of electronics marking systems and products at IPC APEX Expo, April 6-11 in Anaheim, CA. Among other solutions, at its Booth #3823 the company will offer live demonstrations of ILP-30 Slimline Label Feeder for pre-printed label placement. Named for its slender 30mm width – half that of conventional feeders – the label presenter requires only one feeder position on pick & place machines, freeing up valuable space along congested SMT production lines.

Providing precise and accurate placement, IDENTCO’s ILP-30 Slimline Label Feeder is suitable for label sizes from 3mm x 3mm to 25mm x 25mm, and features an integrated compartment that collects liner materials for easy disposal without line stoppage. The module is compatible with many popular pick & place systems, and its reliable electronic operation yields low maintenance costs. The ILP-30 Slimline works best when paired with IDENTCO’s pre-printed labels, and aligns with the company’s emphasis on automation technologies that improve placement accuracy and application speed.

Also at IPC APEX, IDENTCO will provide demonstrations of its recently introduced automated wire marking system whose stamina and speed set new benchmarks for wire and harness label application. The company’s VortexID® can precisely apply up to 20 labels per minute – outpacing other automated units and doubling the most expedient manual setups – and operate 24/7, a stark departure from the single-shift limitations of competing models.

VortexID® features 600dpi printing capabilities, with labels applied via a vacuum plate with a rotating mechanism for reliable application on cylindrical products. Notably, IDENTCO’s new module is materials agnostic, expanding customer choice and potentially decreasing overall labeling materials costs.

IDENTCO also will display its DuraTrack label series, which provides comprehensive traceability for printed circuit boards and electronic components. Engineered for use in surface mount technology and throughout the entire assembly process, DuraTrack thermal transfer printable labels can endure harsh fluxes, the latest cleaning chemistries, and high temperatures encountered in today’s circuit board assembly processes on both sides of the board. As a result, the label series is fully compatible with track & trace incorporation – an increasingly attractive internal quality control and supply chain transparency feature for brand owners producing high-leverage electronics.

Finally, IDENTCO will showcase a series of labels for PCB applications featuring a substrate developed exclusively for IDENTCO by a prominent industry materials and coating supplier. The PCB labels easily withstand prolonged, repeated exposure to the chemicals and high temperatures typical to post-production washing processes. Helpfully, the series is designed for on-demand thermal transfer printing of variable information – a plus for electronics companies incorporating serialization and/or anti-counterfeiting coding into their production practices.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

IDENTCO DuraTrack Stock Label Series Ideal for Circuit Board Assembly

Legacy TTL®100 Series renamed to better reflect the track & trace-promoting advantages of these high-performance PCB labels.

Legacy TTL®100 Series renamed to better reflect the track & trace-promoting advantages of these high-performance PCB labels.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sectors – has renamed its popular stock TTL®100 Series. Now called DuraTrack, the label series for printed circuit boards and electronic components provides printed circuit assemblies with comprehensive traceability – an increasingly attractive internal quality control and supply chain transparency feature for brand owners producing high-leverage electronics.

Engineered for use in surface mount technology and throughout the entire assembly process, DuraTrack thermal transfer printable labels can endure harsh fluxes, the latest cleaning chemistries, and high temperatures encountered in today’s circuit board assembly processes on both sides of the board.

The DuraTrack Series of labels is ideally suited to a wide array of electronics components manufacturing environments, including box builds, internal and external vehicle parts (such as in-cabin infotainment systems and outside sensors), and various other computer unit and PCB assembly settings.

Available in 61 sizes, in both high-performance polyimide and polyester, this off-the-shelf product is available for immediate delivery. The DuraTrack Series can also be customized for those customer applications that require an exact fit.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

IDENTCO Hires Brian Kady as Vice President of Global Sales

Executive brings decades of proven sales success in films, adhesives and coatings to prominent labeling solutions provider.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation, and general industrial sector – has hired longtime materials supply executive Brian Kady as Vice President of Global Sales. He officially joined the company on November 20, and will oversee IDENTCO’s far-reaching sales efforts in the company’s four distinct business units. Mr. Kady also is responsible for sales activities for Reliance Label Solutions, another company under the Industrial Labels Holdings Corp flag.

Most recently, Mr. Kady served as Vice President of Sales at Pregis Polymask, where he drove double-digit sales growth for the protective films company. Before that, he gained ample adhesives and coatings experience during tenures with both Avery and 3M, two of the largest entities in that sector. He also has served as Director of Sales – Performance Adhesives Group for Ohio-based Mactac.

Mr. Kady joins IDENTCO at a promising time. The company has been steadily adding to its extensive portfolio of labeling solutions, which it designs, manufactures and supplies for demanding sectors such as automotive components, electronics applications, industrial machinery & tools, and commercial transportation. In addition, IDENTCO recently introduced VortexID®, an automated wire marking system whose throughput and durability set new industry benchmarks.

“Brian is a people-first yet results-driven business development executive with a track record of expanding revenue growth and extending market share,” said Brad Zechman, CEO of IDENTCO. “As IDENTCO continues to bolster and broaden our solutions portfolio across each of our four main business units, Brian’s industry experience and leadership qualities will be a tremendous asset.”

Mr. Kady earned an MBA from Walsh College in Troy, Michigan, and a bachelor’s degree from Central Michigan University in Mt. Pleasant, MI.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

At Productronica, IDENTCO to Showcase New Automated Wire Marking System and Enhanced Polyimide Masking Products

Ideal for applying self-laminating & flag labels to wires, company’s durable VortexID® can handle up to 20 products/min and operate 24/7.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation and general industrial sectors – will feature its rugged new automated wire marking system at Productronica, November 14-17 in Munich. At Stand A2.557, the company will offer live demonstrations of VortexID®, whose stamina and speed raise benchmarks for wire and harness label application.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation and general industrial sectors – will feature its rugged new automated wire marking system at Productronica, November 14-17 in Munich. At Stand A2.557, the company will offer live demonstrations of VortexID®, whose stamina and speed raise benchmarks for wire and harness label application.

In addition, IDENTCO will highlight its ability to supply labels in customized shapes and sizes for precision-dependent surface mount technology (SMT) manufacturing lines, as well as its recently enhanced series of polyimide masking products. The company’s PT Polyimide Discs comprise high-temperature film with silicone adhesive utilized for thermal and electrical insulation. The silicone adhesive’s exemplary release properties offer ample protection. The discs are provided on a liner and supplied on a core or REEL ETM for automated application settings.

VortexID® can precisely place up to 20 labels per minute – outpacing other automated units and doubling the output of even the most efficient manual setups – and operate 24/7, a welcome upgrade from the continuous use limitations of many label applicators. The machine can handle a variety of American wire gauge sizes (AWGs), making is suitable for a broad array of sectors whose products incorporate wires and harnesses – particularly automotive and electronics components manufacturing. It offers high-resolution, 300dpi printing capabilities, with labels applied via a vacuum plate whose rotating mechanism ensures reliable application to cylindrical products.

Notably, IDENTCO’s VortexID® is materials agnostic, expanding customer choice and potentially decreasing overall materials costs. The unit can apply both self-laminating and flag labels, an attractive two-for-one modularity accomplished by an interchangeable applicator. This versatility by design is another differentiator, providing customers with a flexible solution that eliminates the need to purchase specific machines for each label type. For both types, the VortexID’s application consistency and repeatability ensure neat, secure labels whose crucial product traceability and electronics testing information must be pristinely printed and unobscured.

Still, the new unit’s robustness may be its most groundbreaking strength. While most automated applicators in its space max out at eight hours of continuous use, VortexID® can operate continuously, processing thousands more products per day.

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.

At SMTA Guadalajara, IDENTCO to Showcase New Automated Wire Marking System, and Tout Local Engineering Expertise

Ideal for applying self-laminating & flag labels to wires, company’s durable VortexID® can handle up to 20 products/min and operate 24/7.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation and general industrial sectors – will feature its rugged new automated wire marking system at SMTA Guadalajara, October 25-26, 2023. At Booth 1214, the company will offer live demonstrations of VortexID®, whose stamina and speed raise benchmarks for wire and harness label application. This marks the first time IDENTCO is exhibiting the new solution, which entered the marketplace earlier this year.

Ingleside, IL – IDENTCO – a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation and general industrial sectors – will feature its rugged new automated wire marking system at SMTA Guadalajara, October 25-26, 2023. At Booth 1214, the company will offer live demonstrations of VortexID®, whose stamina and speed raise benchmarks for wire and harness label application. This marks the first time IDENTCO is exhibiting the new solution, which entered the marketplace earlier this year.

In addition, in advance of the show, IDENTCO has announced that one of its longstanding label application engineers, Cesar Ramos, is relocating to the Guadalajara area. The move provides existing and potential customers in the region with even more hands-on, optimized service.

VortexID® can precisely place up to 20 labels per minute – outpacing other automated units and doubling the output of even the most efficient manual setups – and operate 24/7, a welcome upgrade from the continuous use limitations of many label applicators. The machine can handle a variety of American wire gauge sizes (AWGs), making is suitable for a broad array of sectors whose products incorporate wires and harnesses – particularly automotive and electronics components manufacturing. It offers high-resolution, 300dpi printing capabilities, with labels applied via a vacuum plate whose rotating mechanism ensures reliable application to cylindrical products.

Notably, IDENTCO’s VortexID® is materials agnostic, expanding customer choice and potentially decreasing overall materials costs. The unit can apply both self-laminating and flag labels, an attractive two-for-one modularity accomplished by an interchangeable applicator. This versatility by design is another differentiator, providing customers with a flexible solution that eliminates the need to purchase specific machines for each label type. For both types, the VortexID’s application consistency and repeatability ensure neat, secure labels whose crucial product traceability and electronics testing information must be pristinely printed and unobscured.

Still, the new unit’s robustness may be its most groundbreaking strength. While most automated applicators in its space max out at eight hours of continuous use, VortexID® can operate continuously, processing thousands more products per day.

“With demand surging, customer needs for high-volume wire and harness manufacturing continue to rise, prioritizing solutions that automate key processes along the production line – including the labeling process,” said Cesar Ramos, Label Application Engineer for IDENTCO. “We designed the VortexID® automated wire marking unit with speed and durability in mind, combining high throughput and continuous operation with precision printing and label placement for long-term information readability.”

# # #

About IDENTCO

IDENTCO is a designer, manufacturer, and supplier of high-performance labeling solutions for several demanding industries, including automotive components, electronics applications, industrial machinery & tools, and commercial transportation. The company specializes in exactingly engineered labels, ribbons, applicators and printers for product tracking & tracing, branding, compliance, and identification.

IDENTCO has a decades-long reputation with leading OEMs and contract manufacturers for exemplary products, discerning quality management, operational proficiency, and collaborative customer support. A global presence allows IDENTCO to truly understand the markets it serves – including mission-critical needs and pain points – as well as to develop and apply efficiency-instilling, cost-saving labeling standardization processes wherever possible.